Tag

Customer Stories

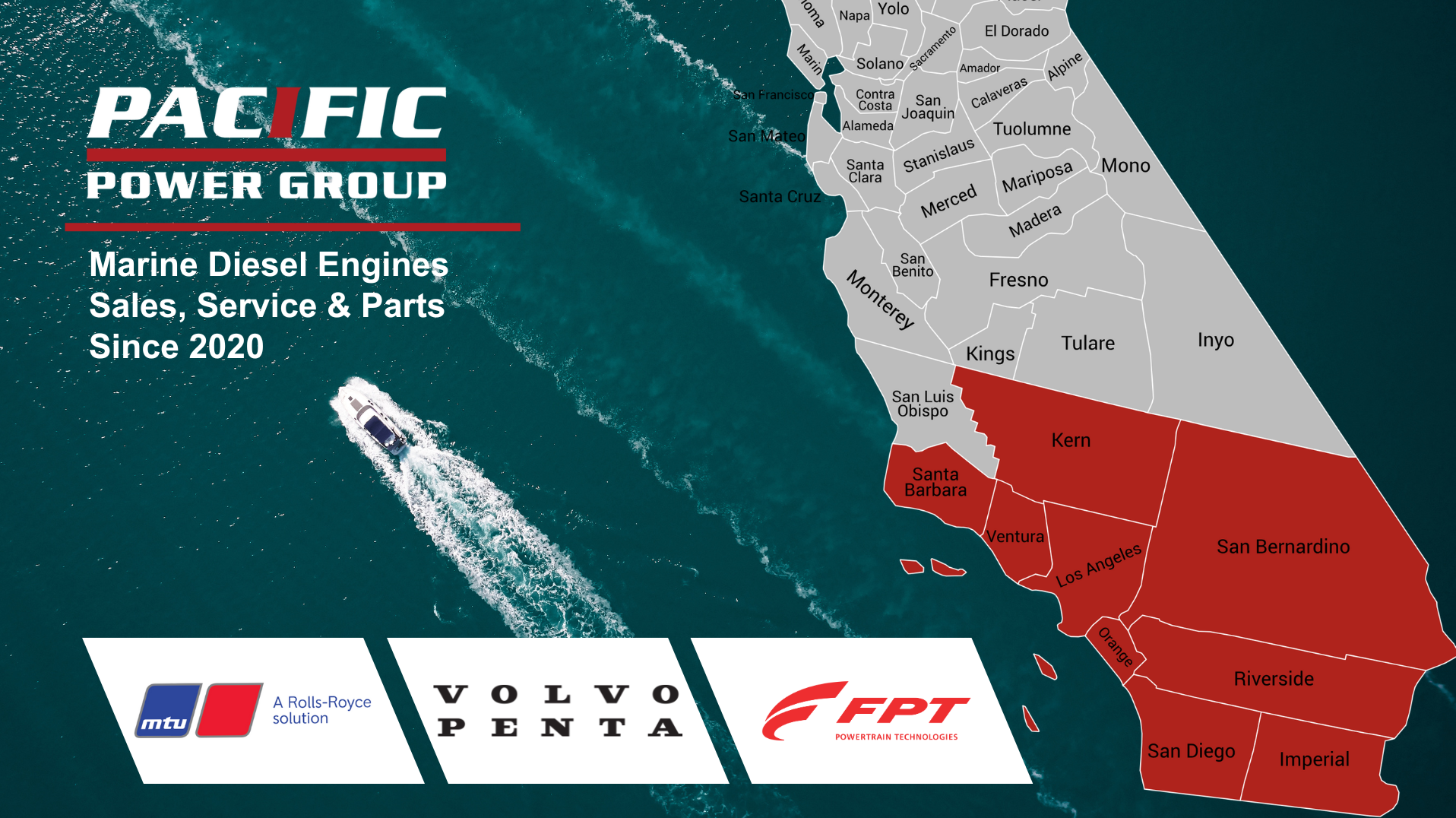

Pacific Power Group: Anchoring Maritime Operations in San Diego and South California

In Southern California, Pacific Power Group (PPG) operates as a key resource for marine propulsion needs, specializing in mtu parts and service. In San Diego, PPG is your source for a wide range of vessels from commercial vessels to leisure crafts. As an authorized mtu distributor, Pacific Power Group stocks parts and provides fast...

Shadowfax Repower Features Newest Volvo Penta DPI Sterndrives

Gregg Williams’ boating season last year didn’t go quite as planned. Problems with the drives on his 30-foot monohulled Sea Sport named Shadowfax forced him to miss time on the water. It also left him in a bit of a predicament – buy a new boat or repower Shadowfax. Williams shopped around a bit, but...

Mavrik Marine Selects MTU Engines for New Ferry

A newly designed fast ferry that will soon go into service in the San Francisco Bay Area will reshape the commute for thousands of residents, giving them a faster option. The 300-passenger fast ferry named Dorado is being built by Mavrik Marine Inc. of La Conner, Washington, and will be powered by a pair of...

Gunderson Marine Utilizes Volvo Penta Engines to Meet Emission Standards

The newest articulated tank barge Gunderson Marine is building for Overseas Shipholding Group will be one of the first in the world to be dual certified as meeting EPA Tier 3 and IMO III emission standards. The barge is reaching this monumental milestone because of the Volvo Penta engines recommended by our marine team to...

MTU Powers North America’s First Tier 4 Final Log Stacker

A 50-year legacy of building innovation in its log stackers continues for Komatsu, which recently unveiled its newest version, the 45 Series electric log stacker that becomes the first in North America to use a Tier 4 engine. Letourneau Inc., a subsidiary of Komatsu, built two log stackers that are using MTU Series 6R1300 EPA...

Font Resize

Contrast