This test checks that the generator can operate at full capacity during outages, confirms proper function of all

major systems, and helps prevent problems like wet stacking and carbon build-up from low or no-load use.

Generator Service & Support

KEEP YOUR POWER ON – NO MATTER WHAT

Protect your on-site power system before problems strike. Whether you rely on backup power for your business, home, or equipment, routine maintenance is key. Serving Oregon, Washington, California, Alaska, and Hawaii, our expert team provides comprehensive inspection and maintenance services for generators and automatic transfer switches to keep your systems operational and running reliably.

GENERATOR SERVICES

• 24/7 emergency support

• NFPA 110 & confidence testing

• Preventative maintenance

• Extensive parts inventory

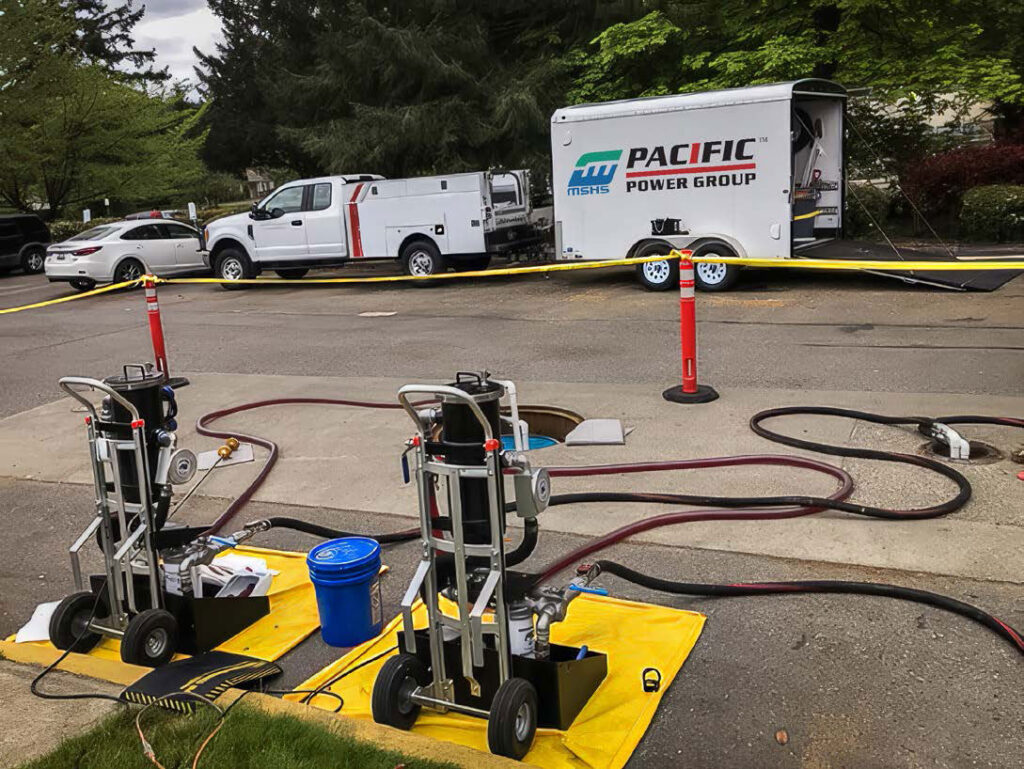

• Fuel polishing and system maintenance

• Diesel fuel sampling

• Diesel auxiliary tanks/day tanks

• Block heaters

• Emission and exhaust systems

• After treatment systems

• Custom enclosures

SUPPORT SYSTEMS WE SERVICE

• Automatic transfer switches.

• Manual transfer switches/docking stations.

• Paralleling switchgear systems.

• Remote system monitoring and diagnostics.

• Load banks, resistive, and reactive testing.

Why Choose MSHS PPG?

-

Rapid Response: Our service centered are strategically located to get technicians on-site fast when you need us.

-

Universal Expertise: We service all major makes and models of stationary, standby, and emergency generators and automatic transfer switches (ATS).

-

Certified Professionals: Every repair and overhaul is performed by factory-trained, certified service technicians.

-

Proactive Protection: Comprehensive maintenance plans designed to catch failures before they happen.

Official Generator Service Provider for Washington State

We are proud to hold the Washington Department of Enterprise Services (DES) Statewide Contract #06225. This specialized contract allows us to provide streamlined, pre-approved generator services to over 1,800 publicly funded organizations across Washington.

FULL-SERVICE MAINTENANCE

3-POINT POWER SECURITY PLAN

Protect your investment with regular service that keeps your generator ready at all times for any scenario:

Annual and Bi-Annual Inspections

Regular maintenance ensures your Emergency System runs reliably and helps catch issues early

before they become an expensive problem.

Fluid and Filter Changes

Regular oil, coolant, and filter changes keep engines running reliably, extend engine life, and prevent costly

failures and downtime.

Fuel Polishing

Ensure your emergency power system is reliable and NFPA compliant with MSHS Pacific Power Group’s mobile fuel polishing and testing services. Because fuel contamination—such as water and sludge—is the leading cause of diesel engine failure, our multi-stage filtration process is designed to decontaminate and stabilize fuel stored in standby systems. We remove harmful sediment and microbiological growth, restoring your fuel to a clean, usable state.

To remain in compliance with NFPA standards, all diesel-powered generators require annual fuel testing. We provide these essential tests along with customized maintenance programs tailored to your specific needs. Contact us today to schedule your annual service and protect your equipment from untimely and expensive failures.

EGSA Certified Technicians

All of MSHS Pacific Power Groups journeyman level power generation technicians are certified by the Electrical Generating Systems Association (EGSA). Certification is our industry’s hallmark of expertise and proficiency in installation, service, maintenance and repair, and knowledge of all components comprising complex power generation systems. EGSA certification assures that technicians have the qualifications to provide exceptional service to critical systems of all brands.

The safety of customers and employees is our highest priority. All technicians receive regular high and low voltage electrical training and NFPA-70E arc flash safety training and all technicians receive arc flash rated clothing and personal protective equipment, and receive regular instruction in its use. We follow a strict Electrical Work Safety program and utilize Lock Out Tag Out procedures when servicing equipment.