Tag

Tug & Tow

MSHS Pacific Power Group Joins SEG Electronics at the 2025 International WorkBoat Show

We’re excited to share that MSHS Pacific Power Group will be participating in the 2025 International WorkBoat Show in New Orleans, one of the industry’s leading events for commercial marine professionals. This year, we are honored to exhibit as a co-exhibitor with SEG Electronics, who invited our team to join them as this year’s key...

See us at the 2024 International WorkBoat Show

The Marine Product Sales team is looking forward to attending The International WorkBoat Show in New Orleans in mid-November. In its 44th year, this show brings the best of commercial marine and innovation together. The MSHS and Pacific Power Group team will be exhibiting in booth 2711 with a focus on engines, engine services, turbochargers,...

MSHS and Pacific Power Group at IMX 2024

MSHS and Pacific Power Group have partnered for this year’s Inland Marine Expo (IMX) to present integrated turnkey marine engine and control system’s services and solutions for the crews and vessels that navigate U.S. inland rivers, lakes, and Intracoastal waterways. At this year’s show: Yanmar 6AY-AM marine diesel engine: Reliable and powerful engine for...

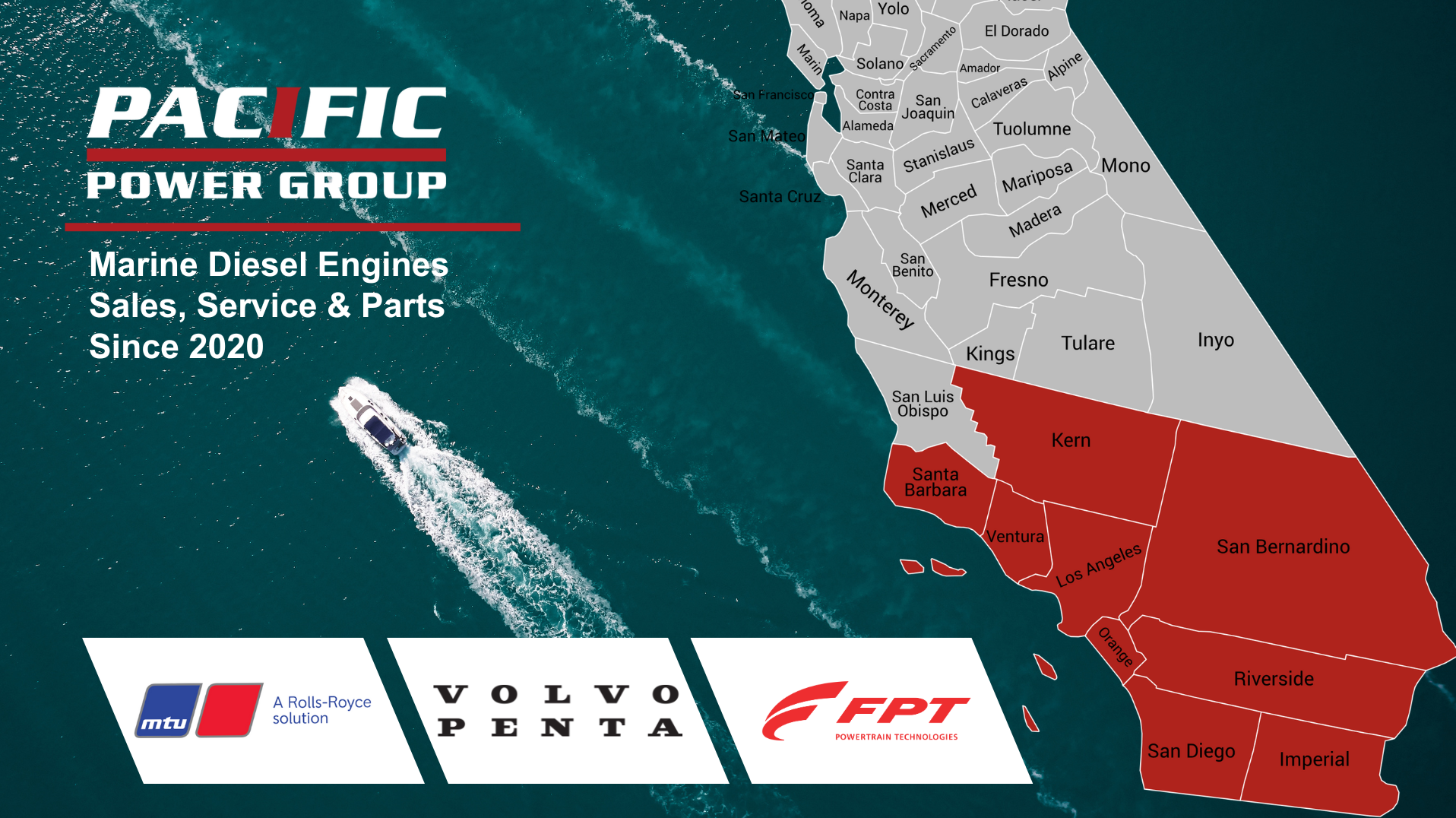

Pacific Power Group: Anchoring Maritime Operations in San Diego and South California

In Southern California, Pacific Power Group (PPG) operates as a key resource for marine propulsion needs, specializing in mtu parts and service. In San Diego, PPG is your source for a wide range of vessels from commercial vessels to leisure crafts. As an authorized mtu distributor, Pacific Power Group stocks parts and provides fast...

MTU Engines Power New Generation of Tugs for Foss Maritime

Among the list of performance standards Foss Maritime wanted from a new series of 90-short ton bollard tugs it was adding to its fleet was a propulsion system capable of meeting strict emission standards. Our marine team was able to deliver on Foss Maritime’s needs by outfitting each of the four new tugs with two...

Font Resize

Contrast